This post has more of a focus in a sustainable business model, rather than sustainable "design" as such. It then becomes interesting to see a sustainable business model can be "designed", at least for this stage in our period of our time. From a business perspective, a frequently heard buzz word or concept today is that business models need to evolve for companies to be more competitive. I have identified within the environmental industry that the business model used is still a very outdated one.

Having made this analysis it is amazing to see how things come around. At the end of 2004 I had to present my final year project for my degree, studying, in the Chilean Navy, to be an Electronic Warfare Officer (Telecommunications), for civilians it may be easier to understand as a Naval Electronic Engineer. The topic of my final year project, that presented with a friend and classmate of mine, who is a Naval Infantry Marine, was: "Network Centric Warfare and it's applicability to the Chilean Navy".

I was always interested in technology. As such the choice of topic was one that I could follow a personal interest that I could apply to my professional career. On starting my research I found an article that had been published in a magazine called Proceedings, published by the US Naval Institute, it was in essence what my paper was very much based on.

The article can be seen here:

https://acc.dau.mil/adl/en-US/37563/file/9068/NCW-Origin%20and%20Future.pdf

It was interesting in terms of seeing how Command and Control systems, could be taken "philosophically" to the next level. One of the points of the article that most impressed upon me was a side bar that told the story of Network Centric Retailing and the experience that Wal-Mart and General Electric had. This article was published in 1998. I would then find exciting my knowledge in the military could be translated to a civilian business environment, with technologies such as Customer Relationship Management (CRM), Enterprise Resource Planning (ERP), etc... which are basically variations on the same topic.

Let's go forward a few years to December 2006, and we come a across a ground breaking book called

Wikinomics. This book in a way further developed on this concept of network centricity, related to

Metcalfe's Law, where collaboration, enabled by networks, is able to accelerate development and growth in whatever ever area of humanity. So what has this got to do with Sustainability, with infrastructure, with business models? It has a lot. I would say that the world in general is a "faster" place, in every sense. Communications are much quicker. Where in South America, in the 1800s it took several months to know that Fernando VII had been deposed of by Napoleon in Spain, hence sparking the independence movement of Latin America, today we knew within minutes, if not seconds, that Hosni Mubarak had been deposed of in Egypt.

Well technology moves much faster today than it did yesterday, not only that, the market place too. Though the global market has become a "larger" market in geographic size as well as potential volume, it is also smaller. Communication with suppliers is something instantaneous, and anywhere, you don't have to be in your office next to a land line phone to communicate, the same is true with clients. Where time can also be "distance", the elimination or reduction of lost time has made our world "smaller".

As a company, or supplier or service provider, we are not alone in the world. As we embrace new technology and accelerate, so do our competitors. How is it possible to remain competitive, if the catch up cycle also becomes shorter and quicker? How can we have our clients also achieve more competitiveness in order that they may be more successful, that will in turn benefit us as a "provider".

In the world we live in today, this situation has become a fundamental challenge. Today it is, we could say, feasible that a one person operation can compete against "considerably larger" companies and have several competitive advantages. All the competitor has to do is sit on the side lines, poach and pick off business opportunities as they come along in terms of product supply. This is something that affects not only our industry, but we could say almost any product manufacturing industry.

However having said that, we are still tied to evermore sophisticated technologies that are always complex in their integration. However there is also another challenge associated to this, and that is the requirement of what is called "complexity masking". The client doesn't want to, or either needs to know, about the complexities of solutions, the client should be given a straight forward, "simple" solution that addresses the requirements they have.

Below we go into detail as to identify the short comings of this industrial age business model as well as to see what are the viable alternatives to it to be more competitive.

To return to the focus of our discussion, we need to analyse why it seems that environmental aspects of projects have difficulty in achieving the amount of success that they should have. Why is it that having several amounts and types of technologies, that these are not being used to maximum effect. We would say that it is mainly a result of an antiquated business model that is still to a large extent present in the industry. The way projects are generated, to how they are designed, executed, and how the materials are supplied.

This is beyond the mindset of having lineal wasteful technologies, instead of closed loop sustainable solutions. For many years, even till now, there are many water professionals that see stormwater as problem to get rid of as quickly and as far away as possible. This in stark contrast of seeing it as a valuable resource that can "easily" be reused, that is if we know how to reuse it with ease.

In larger and more complex projects, then one might see a consortium being established that can also include eventually developers.This serves to some measure what we previously described as "complexity masking".

In the case of simple industrial age materials and supplies, this model might not be that bad. However in our current age, where we have seen the necessity of implementing materials and technologies that are more advanced and beyond the scope and normal education of professionals involved in the infrastructure industry, we have seen that closer support is required. At the end of the chain are the supposed beneficiaries, who make use of the infrastructure, it must be asked though if they are really benefited, if they are subject to flooding, fires, high urban temperatures, water restrictions, etc..

What are the effects that this Industrial Age Business Model.

Having looked at the Industrial Age model, we can see and analyse, as well as extensively comment on its effects. Of the most notable ones we see that there has been as a consequence significant environmental degradation.

We can say that this is an effect, of not only that type of business model, but also the technology and techniques of that period. However what must be said is that, even if there is newer and more modern technology, if the this business model is still in place, then not much can be achieved until the business model advances to be able to take the most advantage of the technology that is advancing at such a quick pace.

Aside from this we also see that the beneficiaries are not really benefited, as they suffer the consequences of poorly designed infrastructure that creates detriment, not only to the environment, but also to the humans that inhabit those locations.

Today as society and technology advances we have seen in general we have seen how industrial age institutions and governments that are based and work on the same models have not been able to provide adequate solutions to a modern world.

Today we have seen that the power of the internet has been able create viable collaborative models, that through new communication techniques have been able to not only provide a replacement to old methods of communication, but have been able to surpass them in performance.

This fact is something that can be extended to practically every aspect of life. In fact nowadays, unless we are hermits, it is very difficult to not come into contact with some aspect of this collaboration process where we benefit positively from this, whether it is directly or indirectly. As such, and as society starts engaging this model more and more, often unconsciously, businesses will also follow this path, hence to remain competitive it becomes a prime necessity to be able to not only join this tendency, but the smarter and more successful companies will also have to be leaders in this aspect. Those who fall behind will also see their success affected.

So how does this new business model look like for the industry that is involved in Sustainable Infrastructure? I have come to name it a Wikinomic Business Model as it closely follows, out of necessity this collaboration model.

In the above model we see the appearance of a new element called an

Integrated Solution Provider. This new entity is something not really seen before as it is not a traditional supplier, it is not a traditional consultant or designer either, as normally these two parties would normally be separated and segregated, if not for "accidental" reason, but also for transparency. Maybe for the past it was a viable and feasible option, however the situation now no longer allows this, if at the same time one expects to be a market leader, in their respective industry.

So how specifically is this new model applied to the infrastructure industry and it’s associated entities and stakeholders, that interact with it. In the diagram we can see that to a certain extent we are already implicitly seeing the effects of a Wikinomic business model, however this is a situation that has come about more by accident than by purpose.

Though we can say that users, buyers or we could be more general in saying consumers, are the generators as their demand generates the requirement from infrastructure, that the market should demand something could be argued stems back to when Adam Smith had talked about the “invisible hand”. However this not totally true as governments sometimes create artificial situations, in Australia there is a fantastic example to illustrate this: Canberra. The existence or foundation of Canberra is obviously a situation that is not in any way related to an "Invisible Hand", but rather an artificial political decision.

The executors become more integrated as they try to achieve economies of scale, working more as team if not purposefully at least it is done on a practical level with many cases of companies, doing Design and Construct, as well others such as EPC, EPCM, etc…

EPC and EPCM do not consider an Integrated Solution Provider within their model, the supplier is external to the “execution”, simply supplying material, if not conforming to a specification in more complex applications given by the designing consultant. If we look at the most “complex” applications in buildings such as elevators, electrical systems, or similar, the supply of these components is done conforming to specifications that are given, there is not that much that a supplier does to add or multiply value to a project.

That a supplier should also participate in the design of a piece of infrastructure is practically unheard of, again even if were are talking about interesting structural composite elements, at most specific characteristics are taken account such as weight, strength, flexibility, etc… however these aspects are simple compared to systems that have apart from having structural and physical characteristics, that also have influences much beyond these in terms of: water management, HVAC design, energy consumption, biology, the list can go on, it is very difficult for even a multi-disciplinary team to manage, with competence, all of these considerations.

For people involved in the business of the environment or sustainability it is time to simply realize that with what has been done till now, the way projects have been undertaken, they are simply not sustainable at several levels. Trying not to preach to the choir, the equation is very simply, if we want to build infrastructure that is sustainable it has to be precisely that. In a world of finite resources, and where human presence more often than not brings damage to the environment where it is, the objective is very clear.

Today technology is inherently different from what it used to be, and in the case of environmental applications they are much more efficient in many more ways at many more levels. This is not a coincidence though.

In my experience, it has been very difficult to meet a designer that has been able to do justice to the possibilities that integrated environmental applications offer. This even if it passes economic viability evaluation, which one might say should be one of the main factors to consider. Genuine environmental companies have been successful not because they have applications that are good for the environment, they have been successful because they provide cost effective solutions.

The only way then to implement this technology to maximum effect is to do so directly with the people who create the technology.

Though there are obstacles to this model...

There are powerful elements that oppose efficient and effective solutions, that challenge the status quo or that moves someone’s “cheese”.

It is interesting to see that civilisation might be again individually in control of their most basic resources such as water.

I propose a 3rd model of service utility administration,

“Consumer Owned Decentralized Solutions”, this is the 3rd iteration, depending on the reference one takes, of how utilities are given to consumers. From the first iteration of centralized state owned distribution services, to the 2nd iteration of these being privatised, today the technology exists for individuals or families to supply themselves with not only water, but also energy. This model is one much more efficient than the previous 2 and it has come about not only because of economic forces, but also environmental and political ones.

The Intellectual Legacy is one that is critical. It often happens, though fortunately, not always, that with more education the more "certain" people become of things, which sometimes are not true, nor good either. The other inherent problem is that the educational model is one that specializes and hence fragments the mind, someone studying water in more depth might learn more about hydraulics and less about botany, geology or soil mechanics though they are fundamental aspects necessary for correct and integral water management. This is not the fault of the student though.

Water models where developed at the beginning of the 20th century, which was before modern geosynthetics existed.

They consider Runoff expressed in coefficients, however there exists technology such as what provides has performance that goes beyond simple runoff. An example are some horizontal applications such as a modular cells on a roof garden, this application beyond taking the runoff coefficient from 0.95 to a “worst case” scenario of 0.20 with just grass, also beyond reducing the runoff, once the soil has become “saturated” the

hanging water will drop into the cell, this water can also made be made use of, this create another phenomenon I have come to call an “Inverse Compensated Runoff Coefficient”. I have not seen a model yet to incorporate this concept.

Anaerobic digestion is something often portrayed as sustainable. Anaerobic digestion though produces several unsustainable situations, it creates methane that is a greenhouse gas, even if it burnt to produce energy, as it now being done the burning produces carbon dioxide which is again a greenhouse gas. Anaerobic digestion produces sludge, which has to be processed, it can be dried by burning the greenhouse gas methane that the same process provides, however this is very energy intensive, even if the dried sludge is used as fertilizer it still generates a carbon footprint as it transported to where it will be used…It is best to purify water using sustainable techniques that do not produce sludge, that do not produce methane and then carbon dioxide, that do not generate a larger carbon footprint than the already considerable inputs it receives.

In addition to the above we not only have the challenge of the increasing speed of change of technology, but also the integration of this technology is also compounded in its complexity as several factors have to be taken into account for them to be used to maximum efficiency, though the outcomes may be very and extremely simple.

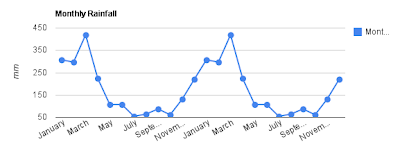

This graph shows how not only the speed of change in terms of technology has increased rapidly, to be able to integrates these leaps in technology. To make maximum use of this technology has become increasingly challenging, though the rewards have also become increasingly beneficial.

One of the reasons we had identified of why the industrial age model occurs, is due to the they way professionals are educated, and then how they are made to work. This till now has been in fragmentation, which is the contrary to collaboration. The closest approximation of collaboration would be a multi-disciplinary team, however this still does not address the core and fundamental aspect that needs to be dealt with. We forget that Universities should teach Universal knowledge, which is why they have that name. This then poses not only a challenge to the industry that makes use of these professionals, but should also engage the education system, at every single level, from national governments down, going to the education providers too.

One of the main sources of the why there is so much of a challenge in terms of being able implement integrated solutions is because the professionals that should design and/or implement them do not have integrated knowledge, the closest thing that can approximate that capacity could be an integrated multi-discipline team, however there is still the challenge of transferring knowledge from the application developers to the designers, and as we have seen this process at this stage can hardly be done quickly enough, and there will be no slowing in pace, only the contrary. As such once more we see the necessity of incorporating Integrated Solution Providers as a fundamental part of a project, through it’s life cycle.

To summarize and conclude then, basically what we see is the necessity for stakeholders in the environmental and sustainable infrastructure industry to understand and then engage in this new business model. This model may not be a perfect one, however it is definitely one much better than the industrial age one, that had or has problems not only in its' functionality but also in its effects.